- Home

- Braemac Blog

- Sensirion STS3x Temperature Sensors Top 6 FAQs

Sensirion STS3x Temperature Sensors Top 6 FAQs | Symmetry Blog

About Augustine Nguyen

1. What are the major differences between the sensors in the STS3x series?

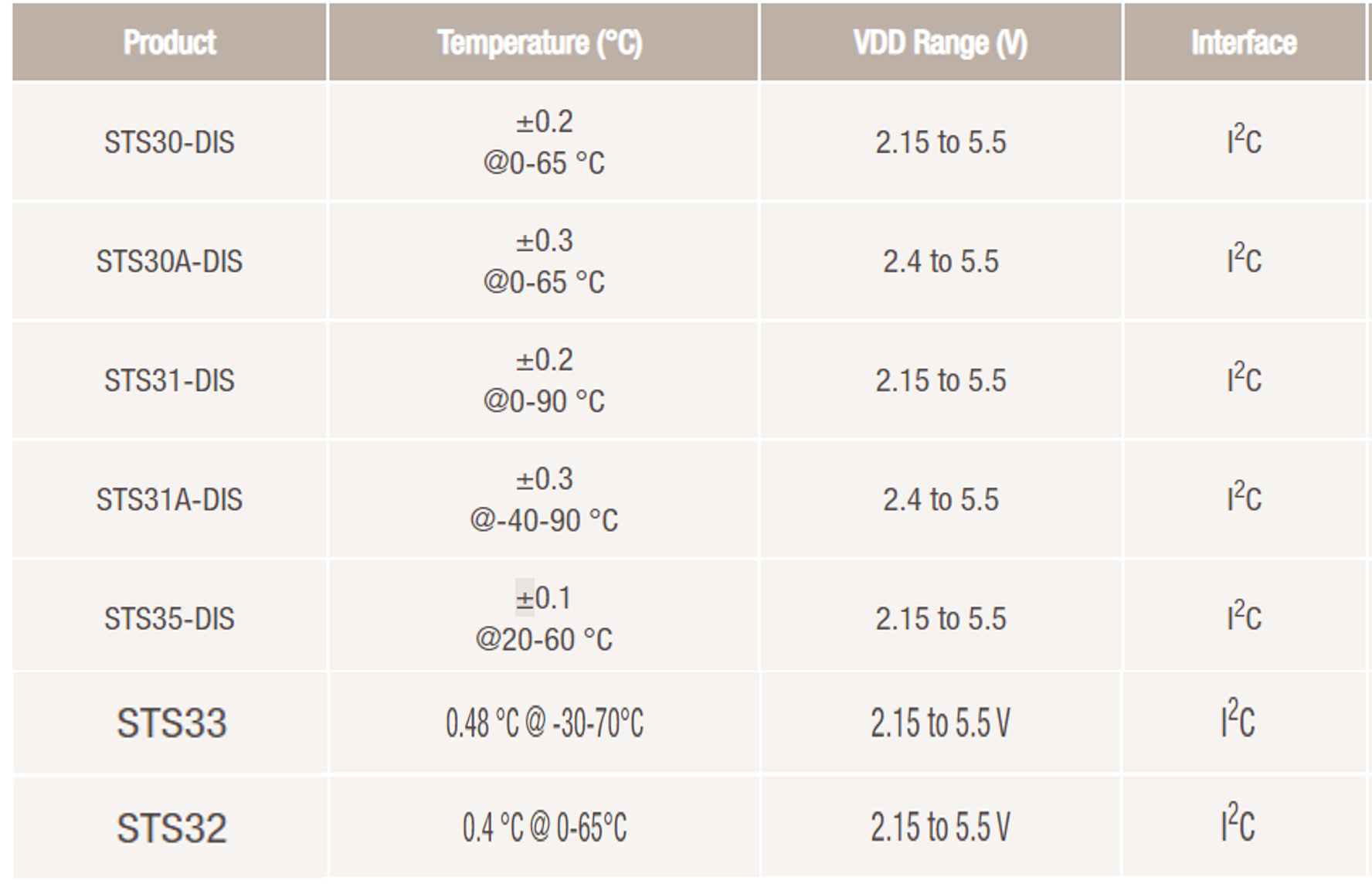

All of the sensor variants differ in terms of the measurement accuracy, supply voltage range, and whether or not they are automotive grade (i.e. STS3xA). Each variant supports I2C interfacing to your respective host MCU. Refer to the table (Figure 1) below for a comparison of all the variants.

Figure 1: Sensirion STS3x temperature sensor series comparison.

Source: Sensirion Environmental and Temperature Sensors & STS32/STS33

2. What does it mean for the STS3x sensors to be calibrated and ISO17025 certified with NIST traceability?

Every STS3x sensor is calibrated with a reference sensor that is NIST traceable through an ISO17025 accredited laboratory. ISO17025 is an international standard of calibration that highlights the general requirements for the competence of testing and calibration laboratories.

One of the requirements of the ISO17025 is for there to be metrological traceability to the SI unit of measurement. This essentially means that the sensor’s measurement results can be related (i.e. traced) to a reference of an unbroken chain of calibrations based on units of measurements that are recognized by national metrology institutes (NIST (USA), PTB (Germany), NPL (UK), etc.). By definition, ISO17025 comprises of but is not limited to NIST traceability. Therefore, an ISO17025 certified sensor is always NIST traceable. Calibration is performed by skilled and certified personnel in certified labs. For more information, refer to the Supplier Calibration Certificate for the STS3x.

3. How are the STS3x sensors calibrated?

Every sensor unit is calibrated at three temperature points: T1 = -30 °C, T2 = 5 °C, and T3 = 70 °C, with the calibration process and certificate accredited with respect to ISO17025. Figure 2 below is an example of the calibration performed at the three temperature points for the STS32. At time of purchase, a certificate of calibration for the specific sensor (specific serial number) is provided (as a PDF) along with digital calibration data (as a .csv file).

Figure 2: Demonstrating calibration performed at the three temperature points for the STS32.

Source: Sensirion

4. Is the 3-point calibration data already integrated in the STS3x sensors at point of purchase?

Although the sensor is calibrated and ready for use, the customer will have to handle the certificate matching on their end. The calibration data points will simply have to be downloaded from Sensirion’s server and merged with the sensor on the customer’s PCB through its unique serial number. This serial number cannot be changed and is hardcoded on the sensor’s OTP memory.

5. What if the sensor is integrated near other potential heat sources on the PCB? Can the customer still leverage the provided certification in this scenario?

This is an important consideration for customers as they will have to ensure that the sensor always matches the environment and not the parasitic heat that could be potentially produced by other components in their PCB design (i.e. power supply, wireless modules, etc.). This can be verified by sending a sensor logging device to a test laboratory that can verify that the STS3x sensor is not affected by any unwanted parasitic heat. If the sensor is designed in properly, customers can still use the calibration certificate that is provided by Sensirion. For more information, reference Sensirion’s STS3x Series Design Guide.

6. Is the STS3x sensor suitable for liquid environments?

Technically yes – if the customer’s design protects the open electrical contacts that are used for soldering the sensor on the PCB. Depending on how harsh the environment is, a protective conformal coating may have to be applied to protect the solder pads from corrosion.

STS3x Temperature Sensors

Buy Now >>