SCD4x CO2 Sensor Frequently Asked Questions | Symmetry Blog

1. What are the main differences between Sensirion's SCD4x (SCD40/1) CO2 sensor and their previous generation, the SCD30?

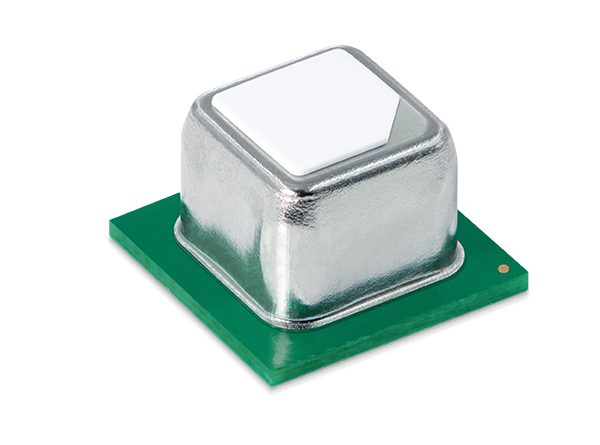

The SCD4x (Figure 1) is a miniaturized CO2 sensor that delivers the same performance as the SCD30, but at the fraction of the price and size. The reduced size of the SCD4x (10.1 x 10.1 x 6.5 mm3) is attributed to its unique CO2 measurement principle that requires fewer integrated components. Compared to the SCD30 (35 x 35 x 7mm), the compact form factor of the SCD4x allows for a much more price-efficient BOM.

Similar to the SCD30, the SCD4x offers an integrated temperature and humidity sensor for measurement compensation. The SCD4x is optimal for high-volume applications, as it is a surface mounted (SMD) component that can be reflow solderable. Conversely, the SCD30 is not meant to be reflow soldered and was designed to be soldered by hand. If your application is a high-volume design that demands accurate CO2 measurements along with strict cost and space-savings, the SCD4x is the best option for you.

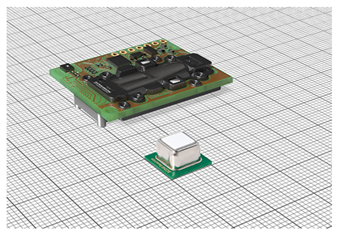

Figure 1: Size comparison of SCD30 (top) and SCD4x (bottom).

2. How was Sensirion able to make the SCD4x drastically smaller than the previous generation, SCD30?

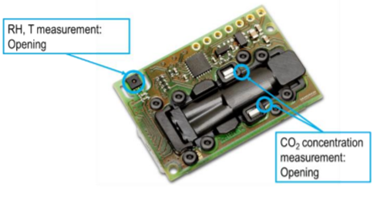

The SCD30 relies on a Dual-Channel Principle (Figure 2), which involves a CMOSense® detector and optical filter in each channel. One channel provides the CO2 measurement by detecting the amount of light that is affected by the presence of CO2 molecules to measure CO2 concentration. The other channel serves as the reference measurement, which only detects light that is not affected by the presence of air molecules. This measurement is used to compensate the CO2 concentration levels that is measured in the other channel for enhanced stability and to offset potential drifts. The Dual-Channel Principle has contributed to the SCD30 sensor’s accuracy and reliability for over 15 years. In fact, many CO2 sensors in the market today employ this same principle.

Figure 2: SCD30 - Dual Channel Openings

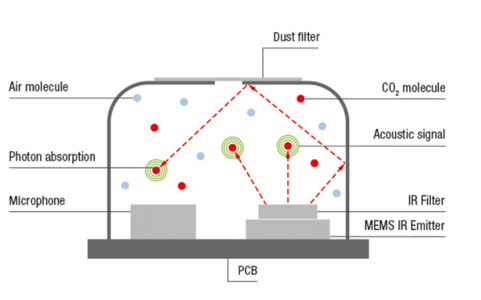

Comparatively, the SCD4x employs the Photoacoustic Sensing Principle (Figure 3), which is based on sound. This varying principle is what allows the SCD4x to scale back its size without compromising on performance, as the sensor sensitivity is independent of the optical cavity. The Photoacoustic Sensing Principle works by emitting light that matches the absorption bands of CO2 molecules from the MEMS IR Emitter (Figure 3) into the closed cell. Once the CO2 molecules in the cell absorb the emitted light, they respond by vibrating, causing the pressure inside the cell to increase. The more CO2 molecules in the closed cell, the more energy from the light that is being absorbed–thus resulting in higher pressure in the cell. Based on this principle, the IR Emitter modulates its light source, causing a periodic pressure change in the measurement cell. This periodic pressure change is measured by the microphone’s signal, which identifies the number of CO2 molecules in the cell and can ultimately be used to calculate CO2 concentration.

Figure 3: SCD4x - Photoacoustic Sensing Principle

3. How does field calibration work for the SCD4x?

The SCD4x sensor includes two calibration algorithms: Field-Calibration (FRC) and Automatic Self-Calibration (ASC). The main difference between FRC and ASC is the source that provides the reference value of ambient CO2 levels. FRC requires the reference value to be manually inputted by the user, while ASC autonomously generates its own reference value by analyzing CO2 levels over a time period. The FRC algorithm is more suitable for particular applications like indoor farming–where the sensor environment is maintained at a specific, controlled CO2 level that varies from the more common 400 ppm (level of CO2 in fresh outside air). The ASC method is ideal for applications where the environment is expected to have the normal atmospheric CO2 concentration of 400 ppm. For example, in a well-ventilated office building over night when there is no human presence. Because ASC calibration does not require manual input from the user, it is the easiest and quickest method of the two. For further details into the calibration methods of Sensirion’s CO2 sensor, refer to Sensirion’s Field Calibration Application Notes that are suitable for both the SCD30 and SCD4x.

4. What are the benefits of monitoring CO2 levels?

When a group of people are indoors, the concentration of CO2 is expected to increase, as humans naturally exhale CO2. However, at high concentrations, humans can experience negative effects, including reduced concentration and a compromised well-being (Figure 4). CO2 sensors like the SCD4x serve to measure and control elevated CO2 concentrations to counteract these negative symptoms. Studies have shown positive effects on productivity and health when CO2 concentrations in an environment are below 1000 ppm. Comparatively, the normal CO2 level for outdoor environments is at around 400 ppm. CO2 sensors can be used to maintain optimal CO2 levels indoors, as their measurements can be used to monitor levels and act accordingly by bringing in fresh air via mechanical ventilation (Demand Controlled Ventilation (DVC), air handling units, etc.) or natural ventilation (open doors or windows).

Figure 4: Indoor levels of CO2 concentration and its effect on well-being.

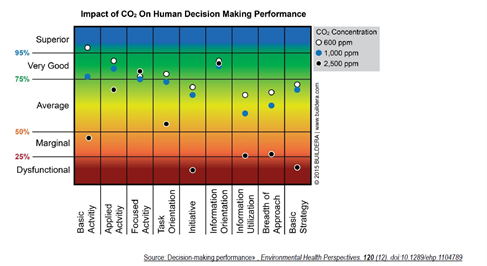

Additionally, studies have shown that high indoor CO2 concentrations have an impact on cognitive and work performance (Figure 5). In a specific test case, individuals that were taking an exam in a room with high CO2 levels of around 2500 ppm generally performed worse and scored lower than when exposed to a CO2 environment at 1000 ppm (Source: NY Times). Moreover, in tighter office spaces like conference rooms, high CO2 levels are often heightened, resulting in a negative impact on human productivity and decision making.

Figure 5: Impact of CO2 on human decision-making performance.

The onset of COVID-19 in 2020 heightened the concern of being exposed to human-exhaled airborne infectious aerosols. In indoor environments, these harmful agents can easily accumulate due to poor air ventilation or contaminated filters from air handling units. To combat this, proper ventilation and exposure to fresh air has become one of the best methods to reduce the risk of infection indoors.

The question then becomes, how can building administrators measure the amount of potential airborne infections indoors? Since buildings generally do not have significant internal sources of CO2 without humans occupying them, the presence of CO2 molecules has become a good indicator of how much exhaled breath is accumulating indoors (which in turn also serves as a good surrogate for human-exhaled infectious aerosols). Sensors like the SCD4x can now play an important role for ventilation systems, as they can accurately determine the levels of airborne viruses indoors and initiate any ventilation needed once CO2 levels exceed a certain risk threshold. The use of such CO2 controlled ventilation systems can also improve energy efficiency, as they are able to optimize the supply of fresh air according to the actual need for outside air as determined by the CO2 sensor.

5. What are the differences between the part number variants in the SCD4x family?

The SCD4x sensor family comprises of two different variants: SCD40 and SCD41. The SCD40 provides base accuracy of ±(50 ppm + 5 % of reading) for the range of 400 ppm to 2000 ppm. The SCD41 is the higher-end variant, offering improved measurement accuracy of ±(40 ppm + 5 % of reading) for an extended range of 400 ppm to 5000 ppm. Additionally, the SCD41 supports Single Shot Mode or single shot measurements (i.e. on-demand measurement).

6. How should the SCD4x be integrated to optimize CO2 sensing?

The most important design considerations when integrating the SCD4x are the following:

- Good exposure to the ambient environment - Sensor placed close to the outer shell of the enclosure with a large cavity.

- Isolation from air turbulences - Sensor isolated from air flow and separate open cavity that is properly isolated from the outside environment.

- Decoupling from vibration sources - No stiff material shared between the sensor or any source of vibration, such as a fan.

- Decoupling from external heat sources - Sensor should not be in close proximity to any large heat sources like the CPU, display, power supplies, etc.

- Shielding from direct sunlight.

- Ensure stable supply voltage.